Product Range

Features

- high measurement accuracy and repeatibility

- Double case Oval Wheel Meter: accuracy: OP up to ± 0.15 % accuracy: OaP up to ± 0.05 %

- Single case Oval Wheel Meter: accuracy: Flowal® Plus up to ± 0.25 % accuracy: OI up to ± 0.1 %

- custody transfer: OIML / MID 2014/32/EU

- international certifications: SIL2, Llyods, Atex, PED, Nace

- approved for use in legal metrology

- mechanical and electronic counters, remote data transmission

Working Principle:

Oval wheel meters are direct volumetric meters for liquids. Their measuring element consists of two toothed precision oval wheels, rolling on each other driven by the fluid pressure. Such a defined amount of liquid is transported through the meter for each rotation of the oval wheels. Therefore the number of revolutions is an accurate measure for the amount of liquid flowing through the meter.

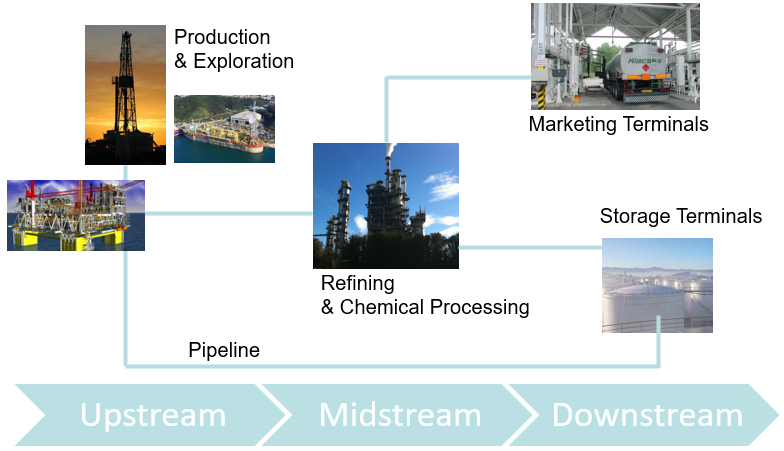

Applications:

- in the oil industry for the measurement of crude oil or refined products or for the measurement of LPG

- in dosing and loading applications for the measurement of defined amounts of various fuels and additives

- in the petrochemical industry for measuring of products such as ethylene or propylene liquid

- in the chemical industry for measuring of various acids or alkalis

- in mechanical engineering for measurement of process liquids or lubricants

- in shipbuilding for measuring of fuel consumption as well as lubricating oil

more on metering skid applications

Accessories:

- Flowcomputer

- Strainer, Gas Separator

- Measuring Skids

- Density Meters

Technical Data

| Nominal size | 6 to 400 mm (1“ bis 16“) |

| Process connection | Females threading Flange according to DIN or ANSI |

| Material |

Pressure relevant: cast steel, stainless steel, PVDF Other wetted parts: PEEK, aluminum; brass, ceramics, stainless steel, others |

| Flow Range | 0,03 l/min to 24.000 l/min, (0.008 gal/min to 6,340 gal/min) |

| Accuracy | ±0,05% to ±0,5% |

| Repeatability | ±0,02% |

| Viscosity | 0,1 to 100.000 mPa·s |

| Process temperature | -40°C to 290°C (-40°F to 554°F) |

| Process pressure | max. 100 bar bar (1,450 psi) |

| Ex-protection | Flame proof or intrinsically safe |

Oval Gear Meters from Bopp & Reuther Messtechnik for high accuracy volume measurement of liquids and liquid gases in loading applications of the chemical and petrochemical industry, petroleum industry and of food and beverages:

Oval Gear Meters from Bopp & Reuther Messtechnik for high accuracy volume measurement of liquids and liquid gases in loading applications of the chemical and petrochemical industry, petroleum industry and of food and beverages: