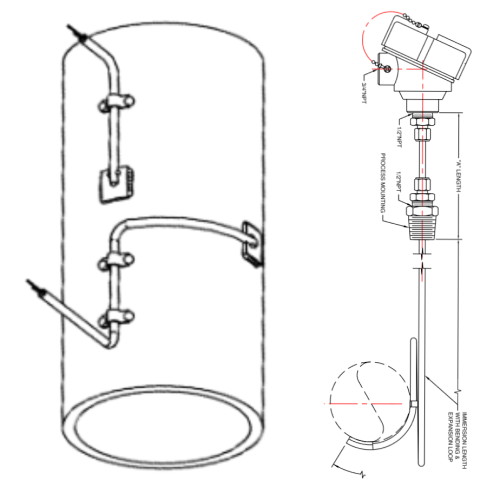

Tube Skin Thermocouples

Tube skin thermocouples provide an efficient means of temperature measurement of tube walls in petrochemical plants and of boiler and super heater tubes in power plants. Made of metal sheath, MgO insulated thermocouple wire the runs can vary from just a few feet to over 50. Shields may be added which curve around the pipe and over the junction and packed with a high temperature insulation to prevent heat from being transferred away from the junction thereby providing a more accurate temperature measurement.

Expansion loops or coils compensate for movement as the tubes are subject to thermal growth. Mounting clamps can be welded along the pipe for additional security.

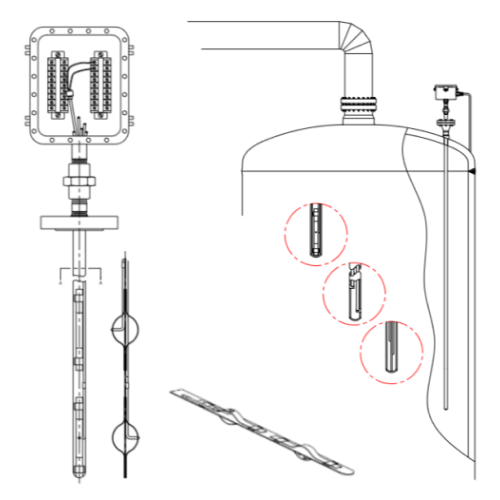

Multicouples

They are used to monitor temperatures at various points with all thermocouples or RTD's contained across a large tank or vessel.

They are used to monitor temperatures at various points with all thermocouples or RTD's contained across a large tank or vessel.

They consist of a junction box suitable for terminating the thermocouples and joining them to cables running back to the measuring instrument.

Multicouples are used in catalytic crackers, limekilns, distillation columns, pressurized reactor vessels and a host of other applications where such profiles are necessary. These type assemblies can be “miniaturized” where they are three feet long with two or three sensors, or they can be any length, even over one hundred feet long with twelve or more sensors.

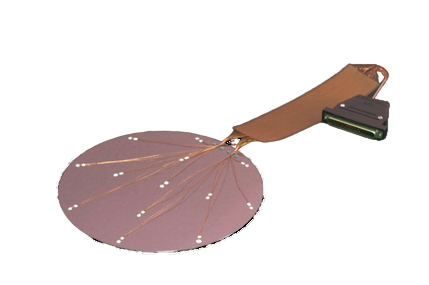

Wafer Sensors

The Instrumented Wafers (Thermocouples, Bonded Wafer or RTDs) finds application in semiconductor processing equipment where knowing and controlling the temperature at the surface of a wafer is critical.

Thermo Electric’s instrumented Wafers are being used in many industries including applications such as Rapid Thermal Processing (RTP), Rapid Thermal Annealing (RTA), Post Exposure Bake (PEB), Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), ION Implantation, Solar Cell, and many other thermally driven processes.

We offer solutions for special temperature applications:

We offer solutions for special temperature applications: