Instrument Calibration

Our PIC Engineering facilities in Shah Alam offer instrument maintenance services including trouble shooting, evaluation, repair, testing and calibration of a wide range of instruments independent of the manufacturer or brand name.

All calibrators are traceable to Sirim certification on accuracy. Calibration stickers and reports are provided for each calibrated instrument.

We provide in-house as well as calibration on site during plant shut-down/maintenance.

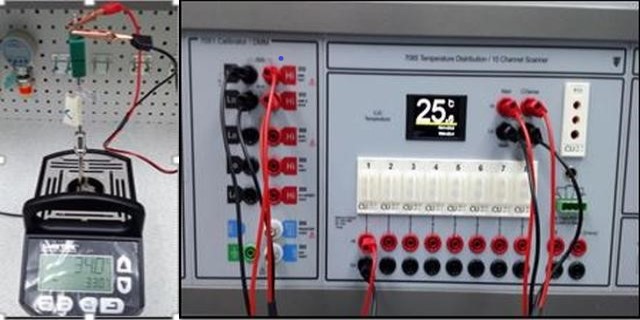

Temperature Calibration

We offer calibration of analog bi-metallic and gas filled sensors, RTDs, thermocouples, thermoswitches, transmitters and other common temperature sensing devices.

We use Dry Block Calibration with calibration procedures for automatic temperature sensor verification in connection with a temperature distribution panel. The analog signal calibration (Zero-ing, Span) for temperature transmitters is done by HART Communicators connected to calibration software.

Pressure Calibration

We offer pressure calibation for absolute, relative, vacuum and differential pressure for Pressure Gauges, digital Gauges and Transmitters.

Range:

- Diff. Pressure: -400 to 400 mbar

- Pneumatic Pressure: -1 to 100 bar

- Hydraulic Pressure: up to 700 bar

Level and Flow - Verification and Calibration

Flow Calibration

- Actual mass calibration is carried out at customer premises using weighing scale to measure the mass and verify with the flow meter.

- Using ultrasonic flow meter we do flow verification against the unit under test flow meter to our master calibrator

- Flow Transmitter calibration to calibrate the Analog signal output/pulse output of the flow meter to the control room/server.

Level Calibration

- RADAR: To verify the reading we dismantle the sensor and calculate the distance to a reference point.

- Differential Pressure: We use digital gauges as a master then measure 5 point at low and high side.

- Displacer Buoyancy: We use dry calibration method to verify the transmitter.